What is Torque?

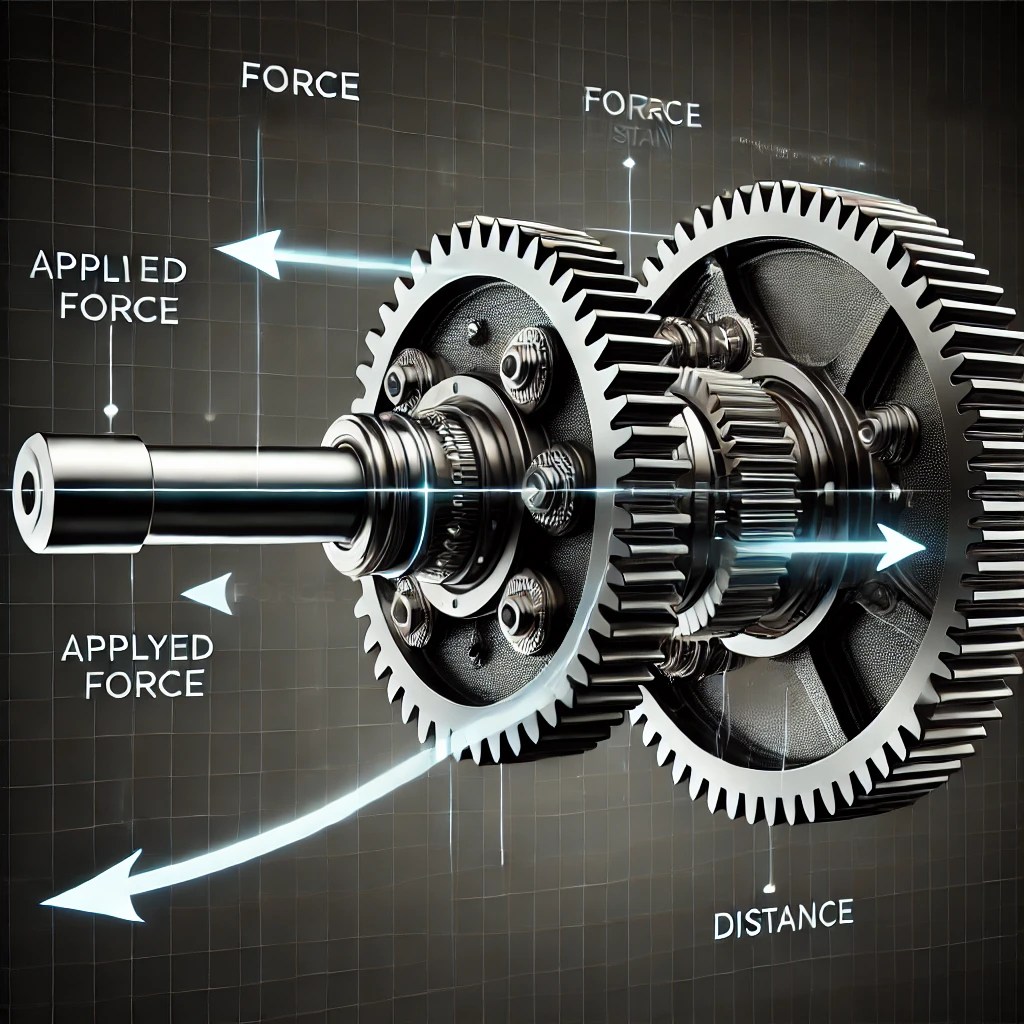

Torque is a fundamental concept in both physics and engineering, representing the measure of the force that produces or tends to produce rotation or torsion about an axis. In simple terms, it can be understood as the rotational equivalent of linear force. When a force is applied to an object at a distance from its pivot point, it generates torque, causing the object to rotate. The effectiveness of this force in creating rotation is influenced by both the magnitude of the force applied and the distance from the axis of rotation, commonly referred to as the lever arm.

Mathematically, torque (τ) can be defined by the formula: τ = r × F, where τ is the torque, r is the distance from the pivot point to the point where the force is applied, and F is the magnitude of the applied force. This equation highlights the relationship between torque and two critical components: the force applied and the distance from the axis of rotation. Increasing either the force or the distance significantly enhances the resulting torque, which is essential in various applications, from loosening a tight bolt to accelerating a vehicle’s wheels.

It is important to note that torque is a vector quantity, which means it has both magnitude and direction. The direction of the torque vector can be determined using the right-hand rule, which states that if you curl the fingers of your right hand in the direction of rotation caused by the force, your thumb will point in the direction of the torque vector. Understanding torque is crucial, as it plays a vital role in the mechanics of machinery, vehicles, and even everyday tools, ensuring graceful and efficient rotational motion.

How is Torque Calculated?

Torque, which is essential in understanding rotational motion, is calculated using a straightforward mathematical formula. The torque (\( \tau \)) experienced by an object can be expressed as the product of the force (\( F \)) applied and the distance (\( r \)), also known as the lever arm, from the pivot point to the point where the force is applied. This relationship is succinctly encapsulated in the equation: \( \tau = r \times F \). Here, torque is measured in Newton-meters (Nm), force in Newtons (N), and the lever arm distance in meters (m).

To illustrate this calculation, consider a simple example: a person using a wrench to loosen a bolt. If the wrench is 0.5 meters long and the person applies a force of 100 Newtons perpendicular to the wrench, the torque exerted on the bolt can be calculated as follows: \( \tau = 0.5 \, \text{m} \times 100 \, \text{N} = 50 \, \text{Nm} \). This indicates that the person applies a torque of 50 Newton-meters to the bolt, demonstrating the effectiveness of using a longer lever arm to achieve a greater rotational effect.

In more complex systems, torque can also be influenced by the angle at which the force is applied. When the force is not perpendicular to the lever arm, the torque can be computed using the equation: \( \tau = r \times F \times \sin(\theta) \), where \( \theta \) is the angle between the force vector and the lever arm. For example, if the same force of 100 Newtons is applied at an angle of 30 degrees, the resulting torque becomes: \( \tau = 0.5 \, \text{m} \times 100 \, \text{N} \times \sin(30^\circ) = 0.5 \, \text{m} \times 100 \, \text{N} \times 0.5 = 25 \, \text{Nm} \).

Understanding how to calculate torque is vital for a variety of applications, from engineering to everyday tasks, ensuring that forces are applied effectively to achieve desired motions.

Units of Measurement for Torque

Torque is a fundamental concept in various fields, especially in engineering and physics, where it is essential to quantify the rotational force applied to an object. The most commonly used unit of measurement for torque is the newton-meter (Nm), followed by the pound-foot (lb-ft) in the United States. Understanding these units of measurement helps in standardizing torque calculations across different applications, facilitating effective communication among professionals.

One newton-meter is defined as the torque that results when a force of one newton is applied perpendicularly at a distance of one meter from the pivot point. This makes the newton-meter particularly relevant in settings where precision is crucial, such as in engineering designs and mechanical systems. On the other hand, the pound-foot is often encountered in automotive contexts and other American engineering applications. The conversion between these units is vital for ensuring compatibility between systems and components designed in different regions, where different unit systems are employed.

Converting torque units is straightforward, owing to the direct relationship between newtons and pounds, as well as meters and feet. For instance, one newton-meter is approximately equal to 0.737562 lb-ft. This conversion is particularly useful when analyzing torque specifications in international projects or when collaborating with teams worldwide. In addition to Nm and lb-ft, other units like kilogram-meter (kg·m) are occasionally used in specific engineering contexts, particularly in metric countries. By ensuring a common understanding of these various torque units, engineers can promote standardization and enhance accuracy in measurement and reporting.

In conclusion, the units of measurement for torque play a crucial role in effectively conveying the rotational force in mechanical and engineering tasks. By understanding the commonly used units like newton-meters and adapting to various conversions, professionals can work collaboratively and efficiently across diverse international projects. This standardization ultimately contributes to improved clarity and operational effectiveness in various industries.

Real-World Applications of Torque

Torque is a fundamental concept that plays a crucial role across various fields, from engineering to everyday life. In the automotive industry, understanding torque is vital for ensuring optimal vehicle performance. For instance, when technicians tighten lug nuts on a car wheel, they apply a specified torque to guarantee that the wheel is securely fastened, preventing accidents due to loose wheels. Additionally, engine components are often calibrated to specific torque settings to maximize efficiency and prevent mechanical failure, illustrating the importance of torque in automotive mechanics.

In the realm of home appliances, torque is equally significant. Electric drills, for example, utilize torque settings to control the power applied during drilling. A higher torque setting is necessary for tougher materials, whereas lower torque can be used for lighter tasks, such as driving screws into soft wood. This adaptability showcases how an understanding of torque optimizes tool performance and enhances user safety and productivity.

Industrial machines also heavily rely on torque calculations. In manufacturing settings, conveyor belts and robotic arms must operate with precise torque to maintain efficiency and avoid mechanical errors. The torque applied to motors needs to be meticulously measured to ensure that machinery operates smoothly without excess wear or risk of malfunction.

Interestingly, the concept of torque extends into the biological realm as well. In biomechanics, torque influences the movements of limbs. For example, when a person lifts an object, the torque generated at the joints is crucial for maintaining balance and control. This interplay between muscle force and torque underscores the importance of understanding this force not just in engineering and machinery but also in human physiology.

Thus, the applications of torque are vast and varied, highlighting its significance in ensuring safety, efficiency, and functionality across a multitude of disciplines.

The Relationship Between Torque and Rotational Equilibrium

Torque, defined as the rotational force acting on an object, plays a critical role in achieving rotational equilibrium. This state occurs when the sum of all torques acting on a body about an axis equals zero, leading to a condition where the object remains at rest or continues to rotate at a constant angular velocity. In simpler terms, a system is in rotational equilibrium when no net torque is produced, ensuring stability in both static and dynamic contexts.

In static systems, such as a seesaw balanced at its midpoint, the torques exerted by the weights on either side must equal one another to maintain equilibrium. For example, if one child weighing 30 kg sits 2 meters from the fulcrum, a child weighing 15 kg must sit 4 meters away to create a counteracting torque. This balancing act exemplifies how torque equilibrium determines the position and stability of static objects.

Dynamic systems also exhibit the principles of torque equilibrium, often under constant motion. Consider the phenomenon of a rotating gyroscope. As it spins, the forces acting on it, including gravitational torque and those from external influences, maintain a balance that allows the gyroscope to resist changes in its orientation. The torque exerted due to the weight of the gyroscope must equally compensate for any external torques to preserve its stability and rotational state.

Understanding the interplay between torque and rotational equilibrium is vital in various fields, from engineering to physics. It provides insights into how forces affect rotational dynamics, enabling the design of stable systems whether stationary or in motion. Consequently, recognizing how balanced torques contribute to stability is essential for both practical applications and theoretical explorations surrounding rotational motion.

Factors Affecting Torque

Torque, defined as the rotational force acting on an object, greatly depends on several key factors. Understanding these factors is essential for both theoretical applications and practical implementations in fields such as engineering and mechanics. The three primary variables that influence torque are the magnitude of the applied force, the length of the lever arm, and the angle at which the force is applied.

The magnitude of the applied force has a direct correlation with torque. In simple terms, the greater the force exerted, the greater the resulting torque. For example, if a person uses a wrench to tighten a bolt, applying a stronger force will increase the torque, thus leading to a more secure connection. However, it is crucial to consider how this force is applied in conjunction with other factors.

Another significant factor is the length of the lever arm, or moment arm, which is the distance from the pivot point (or axis of rotation) to the point where the force is applied. A longer lever arm allows for a larger torque to be generated with the same amount of force. This principle is often utilized in tools such as crowbars and seesaws, where increasing the length of the lever arm significantly enhances efficiency, demonstrating how torque can differ even when the applied force remains consistent.

Lastly, the angle of application plays a vital role in determining the effectiveness of the force applied. Torque reaches its maximum value when the force is applied perpendicular to the lever arm. Deviating from this optimal angle decreases the effective portion of the applied force contributing to torque. For instance, when pushing a door to open it, applying force directly outward from the hinges generates maximum torque, while pushing at an angle reduces it. Understanding these factors provides a comprehensive view of how torque operates in various systems.

Conclusion

In the realm of physics and engineering, torque is a fundamental concept that is essential for comprehending the mechanics of rotational motion. As we have explored in this blog post, torque is defined as a measure of the force causing an object to rotate around an axis. This rotation is influenced not only by the magnitude of the applied force but also by the distance from the axis of rotation, termed the moment arm. Understanding these principles is vital for engineers and scientists alike as they design and analyze systems involving movement.

The significance of torque extends into various practical applications that permeate our daily lives. From the simple action of opening a door to the sophisticated mechanics of engines and machinery, torque plays a crucial role in ensuring that these mechanisms operate efficiently and effectively. Devices such as wrenches utilize the concept of torque to provide the necessary force required to tighten bolts. This illustrates how a deeper understanding of torque can enhance both the usability and safety of everyday tools.

Moreover, in engineering design, torque considerations are essential for ensuring structural integrity and performance. Engineers must account for torque in the design of rotating elements such as gears, flywheels, and pulleys, where improper torque application can lead to mechanical failures or inefficiencies. Therefore, a clear grasp of rotational forces is paramount in the creation of reliable systems that can withstand operational stresses.

In conclusion, torque is not merely an abstract concept but a critical element of both physics and engineering that has significant implications for the functionality and design of various systems. By appreciating the role of torque in everyday life and its applications in engineering, readers are encouraged to engage with the underlying physics that govern rotational forces. This understanding is essential for fostering advancements in technology and improving our interaction with mechanical systems.